Understanding the Numerous Kinds of Welding Techniques and Services Available

Summary of Welding Methods

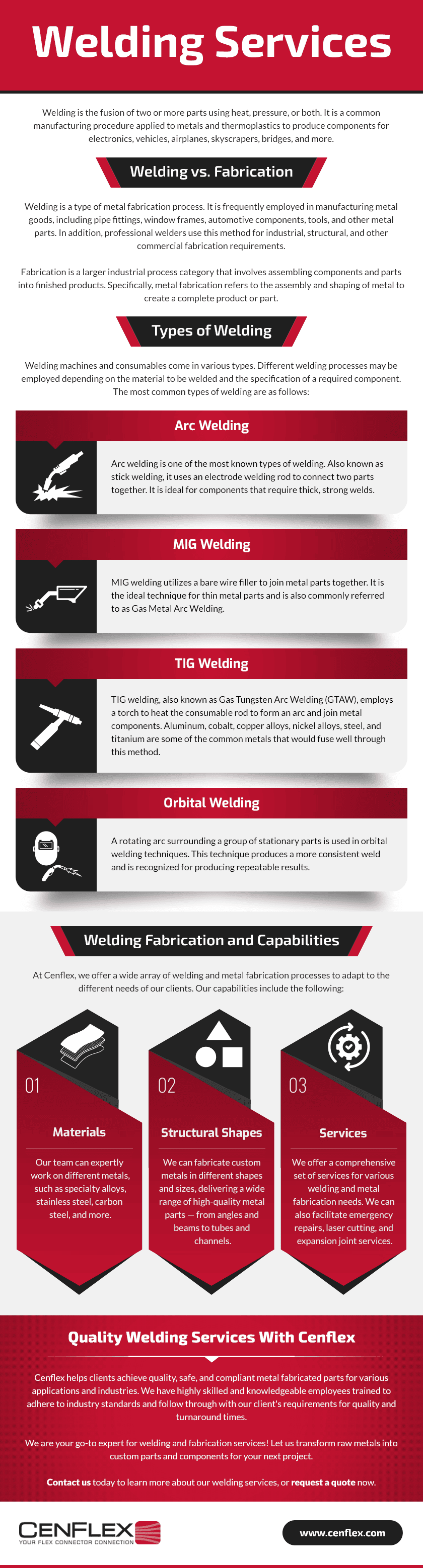

Welding techniques encompass a varied series of techniques used to join materials with each other permanently. One common approach is arc welding, which includes creating an electrical arc in between an electrode and the base material to melt and fuse them together. This technique is functional and can be utilized with various metals, making it one of one of the most commonly used welding processes.

Additionally, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a precise and tidy welding approach that makes use of a non-consumable tungsten electrode to develop the weld. TIG welding is commonly used for thinner products and gives exceptional control over the welding procedure. Overall, recognizing these numerous welding strategies is essential for picking the most suitable method for various tasks.

Generally Made Use Of Welding Techniques

One of the most commonly utilized strategies is Gas Steel Arc Welding (GMAW), additionally recognized as MIG welding. An additional typical method is Protected Steel Arc Welding (SMAW), or stick welding, which utilizes a flux-coated electrode to create the weld - Welding Inspection Service. Flux-Cored Arc Welding (FCAW) is commonly utilized in industrial setups due to its high welding speed and portability.

Advanced Welding Solutions

Building upon the foundation of commonly used welding techniques, the realm of innovative welding solutions includes cutting-edge techniques and modern technologies that press the boundaries of precision and effectiveness in product signing up with processes. Advanced welding services frequently entail specialized methods such as laser welding, electron light beam welding, and friction mix welding. Laser welding utilizes a highly concentrated light beam of light to precisely sign up with steels with very little heat-affected areas, making it optimal for delicate or intricate parts. Electron beam welding, on the other hand, employs a high-velocity electron beam of light to produce deep weld penetrations in materials like aerospace Bonuses alloys or different steels. Friction stir welding, a solid-state signing up with procedure, enables the welding of materials that are testing to fuse utilizing traditional techniques, like aluminum and copper. These innovative techniques use boosted control over the welding process, resulting in stronger, a lot more resilient welds with minimized distortion and improved general top quality.

Specialized Welding Strategies

An additional specialized welding strategy is laser beam of light welding, where an extremely concentrated beam is made use of to join metals with minimal heat-affected areas and distortion. This approach is frequently employed in sectors requiring high precision and cleanliness, such as electronic devices and clinical gadget production. Furthermore, explosive welding is a distinct strategy that utilizes controlled nitroglycerins to bond different steels together, creating reputable and solid joints. These specialized welding strategies display the diversity and advancement present in the area of welding, using options for a vast array of industrial applications.

Selecting the Right Welding Process

With various welding methods offered, it is important to consider variables such as the type of metal, thickness, joint style, and wanted end outcome when picking the ideal welding process. Amongst the common welding approaches are Gas Steel Arc Welding (GMAW), Protected Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) GMAW, additionally recognized as MIG welding, is appropriate for welding thin to thick steels and is flexible in various placements.

Final Thought

To conclude, understanding the numerous types of welding techniques and solutions available is essential for picking the right approach for a certain project. By understanding the generally utilized welding techniques, advanced welding services, and specialized methods, individuals can make educated decisions to ensure the success of their welding jobs. It is essential to think about factors such as materials, task needs, and budget plan when picking the most ideal welding process.

From conventional methods like stick welding to sophisticated procedures such as laser welding, the globe of welding provides a wide variety of alternatives for signing up with steels together.Furthermore, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a precise and clean welding technique that makes use of a non-consumable company website tungsten electrode to create the weld. Advanced welding services usually involve specialized techniques such as laser welding, electron light beam welding, and rubbing stir welding. Among the common welding approaches are Gas Metal Arc Welding (GMAW), Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) By being mindful of the commonly utilized welding techniques, progressed welding solutions, and specialized strategies, people can make informed decisions to guarantee the success of their welding tasks.